Pipes and Rods Surface Modification

- Problem Relevance

- Technology and Equipment for MAM of Pipes and Rods

- Model T15 (Т19) Technical Specifications

Problem Relevance

Mechanical methods, chemical etching or electrochemical polishing typically perform surface finishing of critical parts at machines and devices manufacturing. The labor-intensive and environmentally unfriendly technologies, poorly amenable to mechanisation and automation, do not meet modern production requirements.

One of the technological challenges is the surface finishing treatment of long small diameter tubes, rods and wires.

Technology and Equipment for MAM of Pipes and Rods

The challenging MAM method application area is surface finishing treatment (modification) of zirconium tubes - the nuclear fuel element cladding.

The efficient operation of nuclear reactors and their safety are directly dependent on the manufacturing quality of zirconium fuel assembly components including fuel elements. The nuclear fuel elements operation in water coolant at high temperature and pressure leads to corrosion and hydrogen absorption of their shells; as consequence, limits the service life of these elements. The surface finishing of nuclear fuel cladding determines considerably their performance properties - resistance to corrosion, abrasion, thermal and mechanical failure.

The accident at Fukushima nuclear reactor in 2011 in Japan, occurred due to a sudden coolant loss, set the task of significant increase in corrosion resistance and durability of fuel element cladding. Currently the shells finishing treatment is performed by traditional methods (abrasive belts grinding, etching in hydrofluoric solutions), which exhausted their technological resources.

The Magnetic-Abrasive Modification technology is an alternative to traditional fuel cladding treatment. It forms a modified surface layer of parts with high performance specifications.

The research of the magnetic-abrasive modification of zirconium fuel cladding held by the scientists of Polimag and the Institute of Industrial Nuclear Technologies of the National Research Nuclear University MEPhI (Moscow), found promising industrial application in nuclear engineering.

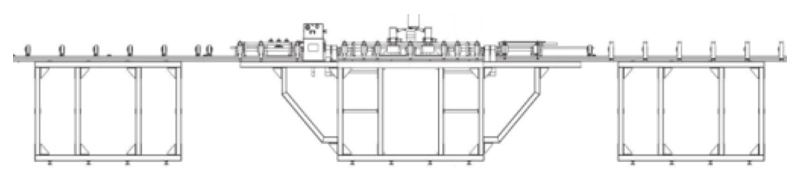

We developed the technology fundamentals of modification of the outer and inner shells surfaces and designed T15 prototype model.

The prototype of the model T15 provides the process of magnetic-abrasive modification at the values of the magnetic induction in the working area up to 1 Tesla.

This process induces active magnetoplastic, magnetoelectric and magnetostrictive effects. Other physical and chemical processes of energy and mass transfer at the atomic and molecular level are activated in the presence of special process fluids. These effects balance the treated material structure and heal many structural defects. As a result the polished surface nanorelief with a minimum of structural defects in the surface layer is formed.

The results of 150 days corrosion tests of fuel-element cladding samples demonstrate the increase in corrosion resistance of the modified samples by 25% compared with the initial.

Model T15 (Т19) Technical Specifications

| diameter of polished parts | 6-15 mm |

| processed pipe length | 0.7-5.0 m |

| simultaneous machining of the outer and inner pipe surface | |

| polished surface nanorelief parameter | Ra < 0,2 µm |

| dimensional metal removal | 10-30 µm |

| polishing performance | 0.5-1.5 m/min |

| power consumption | 2.5 |

| dimensions L x B x H | 11.5 x 0.6 x 1.3 m |

| weight | 220 kg |

The industrial testing of Magnetic-Abrasive Modification technology has been held at one of the Rosatom enterprises (Russia) in 2016. According to the test results in 2018, we created a more advanced T19 model, operating in automatic mode.